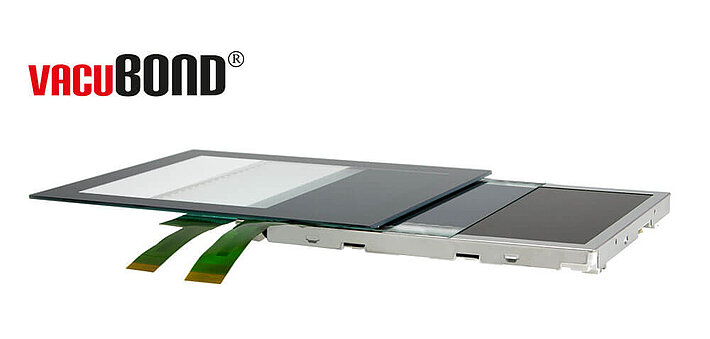

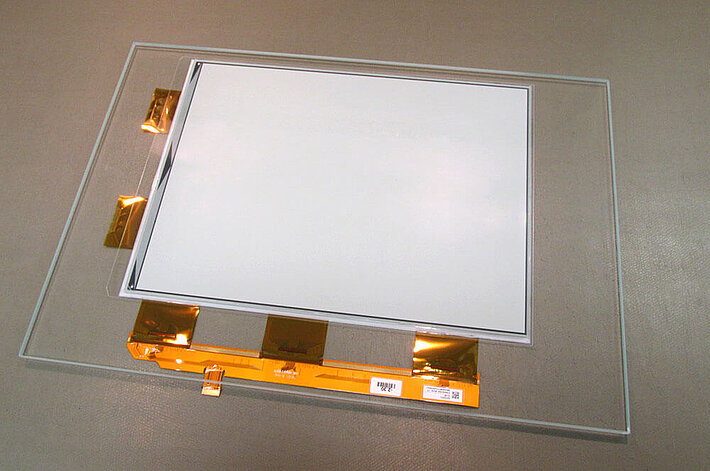

The specialists at FORTEC Integrated and FORTEC United States now possess extensive experience and solid expertise, which is continuously incorporated into the optimization of the process. The vacuum bonding method (also known as direct dry Optical Bonding) enables production free from optical defects and ensures long-lasting material stability without yellowing.

With this process, all types of displays—up to a size of 32 inches—can be reliably processed. Modern, ultra-thin TFT displays with or without bezels, as well as special solutions like round or E-Ink displays, can also be realized with VacuBond®.

A recent video clearly demonstrates the key advantages and diverse applications of the VacuBond® process.